Product Description

Products Description

EP169 CONSTRUCTION

ELEVATOR SPEED REDUCER

Product Features

Manufacturing precision of gear pairs are up to 5~6 grade.

Special lubrication to prevent leakage effectively.

Computer modification technology for gear tooth to improve the carrying capacity of gear pair and reduce noise.

FEA analysis software for optimization of housing design, guarantee strength and stiffness, also improve shaft strength and bearing life.Housing is made by ductile iron, it’s beneficial to sturdy structure, noise and vibration dampening.

HINT FOR USERS:

1. When environmental temperature is under than -5°C, it is required to use synthetic oil.

2. The dimensions and specifications are subject to change without notice.

| Quick Reply | All enquiry or email be replied in 12 hours, no delay for your business. |

| Professional Team | Questions about products will be replied professionally, exactly, best advice to you. |

| Short Lead time | Sample or small order sent in 7-15 days, bulk or customized order about 30 days. |

| Payment Choice | T/T, Western Union,, L/C, etc, easy for your business. |

| Before shipment | Take photos, send to customers for confirmation. Only confirmed, can be shipped out. |

| Language Choice | Besides English, you can use your own language by email, then we can translate it. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery |

|---|---|

| Hardness: | – |

| Installation: | – |

| Layout: | – |

| Gear Shape: | – |

| Step: | – |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide insights into the importance of proper installation and alignment of winch drives?

Proper installation and alignment of winch drives are of utmost importance to ensure optimal performance, longevity, and safety of the system. Here’s a detailed explanation of the significance of proper installation and alignment of winch drives:

- Optimal Performance:

Proper installation and alignment are crucial for achieving optimal performance of winch drives. Precise alignment ensures that the winch drive operates within its designed parameters, minimizing power losses and maximizing efficiency. Accurate installation of components, such as motors, gearboxes, and brakes, ensures that they are properly integrated and aligned with each other. This alignment reduces mechanical stress, minimizes friction, and allows for smooth and reliable operation of the winch drive, resulting in improved performance and productivity.

- Extended Lifespan:

The correct installation and alignment of winch drives contribute to their longevity. When components are misaligned or improperly installed, it can lead to excessive wear, vibration, and premature failure of critical parts. Misalignment puts additional stress on bearings, shafts, gears, and other components, causing accelerated wear and reducing their lifespan. By ensuring proper alignment during installation, the load is distributed evenly, reducing mechanical stress and increasing the lifespan of the winch drive system.

- Reduced Maintenance and Downtime:

Proper installation and alignment can significantly reduce the need for maintenance and minimize downtime. Misalignment or improper installation can cause issues such as excessive heat generation, increased friction, and misoperation of safety mechanisms. These issues can lead to frequent breakdowns and unplanned downtime, resulting in productivity losses and increased maintenance costs. By ensuring correct alignment and installation, the risk of such issues is minimized, reducing the frequency of maintenance and improving overall system uptime.

- Enhanced Safety:

The safety of personnel and equipment is a critical consideration when it comes to winch drives. Improper installation and alignment can compromise the safety of the system. Misalignment can result in unexpected movements, excessive vibrations, or loss of control, posing risks to both operators and the surrounding environment. Proper alignment ensures that the winch drive operates within its intended parameters, reducing the likelihood of malfunctions, accidents, or equipment damage. It is essential to follow manufacturer guidelines and industry standards for installation and alignment to maintain a safe working environment.

- Efficient Power Transmission:

Correct alignment of winch drives ensures efficient power transmission from the motor to the drum or load. Misalignment can lead to power losses, increased energy consumption, and reduced overall system efficiency. Proper alignment ensures that the power is transmitted smoothly and efficiently, minimizing energy wastage and optimizing the performance of the winch drive. This not only improves energy efficiency but also reduces operating costs over the lifespan of the system.

In summary, the proper installation and alignment of winch drives are essential for achieving optimal performance, extending the lifespan of the system, reducing maintenance and downtime, enhancing safety, and ensuring efficient power transmission. Following manufacturer guidelines, industry standards, and engaging experienced professionals during installation and alignment processes is crucial to maximize the benefits and longevity of winch drive systems.

How does the design of winch drives impact their performance in different environments?

The design of winch drives plays a critical role in determining their performance in different environments. Various design factors influence the reliability, efficiency, and adaptability of winch drives to specific operating conditions. Here’s a detailed explanation of how the design of winch drives impacts their performance:

- Load Capacity and Power:

The design of winch drives directly affects their load capacity and power capabilities. Factors such as motor size, gear ratio, and drum diameter determine the maximum load capacity a winch drive can handle. The power output of the motor and the mechanical advantage provided by the gear system impact the winch drive’s ability to lift or pull heavy loads effectively. A well-designed winch drive with appropriate load capacity and power ensures optimal performance in different environments.

- Speed and Control:

The design of winch drives influences their speed and control characteristics. The gear ratio and motor specifications determine the speed at which the winch drive can operate. Additionally, the presence of a variable speed control mechanism allows for precise and controlled movement of loads. The design should strike a balance between speed and control, depending on the specific application and operational requirements in different environments.

- Drive System:

Winch drives can utilize different drive systems, such as electric, hydraulic, or pneumatic. The design of the drive system impacts the performance of the winch drive in different environments. Electric winch drives are commonly used due to their ease of use, precise control, and suitability for various applications. Hydraulic winch drives offer high power output and are often preferred in heavy-duty applications. Pneumatic winch drives are suitable for environments where electricity or hydraulics are not readily available. The design should align with the specific requirements and constraints of the environment in which the winch drive will be used.

- Enclosure and Protection:

The design of the winch drive enclosure and protection features significantly impacts its performance in different environments. Winch drives used in outdoor or harsh environments should have robust enclosures that provide protection against dust, moisture, and other contaminants. Sealed or weatherproof enclosures prevent damage to internal components and ensure reliable operation. Additionally, features such as thermal protection and overload protection are designed to safeguard the winch drive from overheating or excessive strain, enhancing its performance and longevity.

- Mounting and Installation:

The design of winch drives should consider the ease of mounting and installation. Mounting options such as bolt-on, weld-on, or integrated mounting plates offer flexibility for different installation scenarios. The design should also take into account the space constraints and mounting requirements of the specific environment. Easy and secure installation ensures proper alignment, stability, and efficient operation of the winch drive.

- Control and Safety Features:

The design of winch drives includes control and safety features that impact their performance in different environments. Control systems can range from simple push-button controls to advanced remote controls or integrated control panels. The design should provide intuitive and user-friendly control interfaces for efficient operation. Safety features such as emergency stop mechanisms, load limiters, and overload protection are crucial to prevent accidents and ensure safe operation in various environments. The design should prioritize the incorporation of appropriate safety features based on the specific application and environmental conditions.

By considering these design factors, winch drives can be optimized for performance, reliability, and safety in different environments. A well-designed winch drive that aligns with the specific requirements of the environment will deliver efficient and effective lifting or pulling capabilities while ensuring long-term durability and functionality.

Can you explain the key components and functions of a winch drive mechanism?

A winch drive mechanism consists of several key components that work together to provide controlled pulling or lifting capabilities. Each component has a specific function that contributes to the overall operation of the winch drive. Here’s a detailed explanation of the key components and their functions:

- Power Source:

The power source is the component that provides the energy to drive the winch mechanism. It can be an electric motor, hydraulic system, or even a manual crank. Electric motors are commonly used in modern winches due to their efficiency, controllability, and ease of operation. Hydraulic systems are often employed in heavy-duty winches that require high pulling capacities. Manual winches, operated by hand-cranking, are typically used in lighter applications or as backup systems. The power source converts the input energy into rotational motion, which drives the other components of the winch mechanism.

- Gearbox or Transmission:

The gearbox or transmission is responsible for controlling the speed and torque output of the winch drive. It consists of a series of gears arranged in specific ratios. The gears are engaged or disengaged to achieve the desired speed and torque requirements for the application. The gearbox allows the winch drive to provide both high pulling power or low-speed precision, depending on the needs of the task. It also helps distribute the load evenly across the gear teeth, ensuring smooth and reliable operation.

- Drum or Spool:

The drum or spool is a cylindrical component around which the cable or rope is wound. It is typically made of steel or other durable materials capable of withstanding high tension forces. The drum is connected to the rotational output of the gearbox or transmission. As the gearbox rotates, the drum winds or unwinds the cable, depending on the direction of rotation. The diameter of the drum determines the pulling or lifting capacity of the winch drive. A larger drum diameter allows for a greater length of cable to be wound, resulting in increased pulling power.

- Cable or Rope:

The cable or rope is the element that connects the winch drive to the load being pulled or lifted. It is typically made of steel wire or synthetic materials with high tensile strength. The cable is wound around the drum and extends out to the anchor point or attachment point of the load. It acts as the link between the winch drive and the object being moved. The choice of cable or rope depends on the specific application requirements, such as the weight of the load, environmental conditions, and desired flexibility.

- Braking System:

A braking system is an essential component of a winch drive mechanism to ensure safe and controlled operation. It prevents the cable or rope from unwinding uncontrollably when the winch is not actively pulling or lifting a load. The braking system can be mechanical or hydraulic, and it engages automatically when the winch motor is not applying power. It provides a secure hold and prevents the load from slipping or releasing unintentionally. The braking system also helps control the descent of the load during lowering operations, preventing sudden drops or free-falls.

- Control System:

The control system allows the operator to manage the operation of the winch drive. It typically includes controls such as switches, buttons, or levers that enable the activation, direction, and speed control of the winch. The control system can be integrated into the winch housing or provided as a separate control unit. In modern winches, electronic control systems may offer additional features such as remote operation, load monitoring, and safety interlocks. The control system ensures precise and safe operation, allowing the operator to adjust the winch drive according to the specific requirements of the task.

In summary, a winch drive mechanism consists of key components such as the power source, gearbox or transmission, drum or spool, cable or rope, braking system, and control system. The power source provides the energy to drive the winch, while the gearbox controls the speed and torque output. The drum or spool winds or unwinds the cable, which connects the winch drive to the load. The braking system ensures safe and controlled operation, and the control system allows the operator to manage the winch’s performance. Together, these components enable winch drives to provide controlled pulling or lifting capabilities in a wide range of applications.

editor by Dream 2024-05-16

in Dehradun India sales price shop near me near me shop factory supplier Vertical Installation Electric Motor Cycloidal Reducer Bl6 Bld6 XL9 Xld9 Gearbox manufacturer best Cost Custom Cheap wholesaler

Our item range involves all sorts of helical equipment, spur gear, bevel equipment, equipment rack, worm equipment, sprockets,chains, bearings. There is a technological centre of province amount, EPG academician doing work station, experiment station for EPG publish doctors, and nationwide 863 program set up in EPG group. With these platforms and strong technological capability, the far more than 400 professionals have developed all assortment of particular high precise and large toughness merchandise, conducted mold packages for crucial elements in the car and countrywide business revitalizing system, ensuing more than 5000 created in excess of, among which 33 items are autonomous patent engineering with 4 patent accredited . In this way, our goods have continued to acquire marketplace acceptance and buyers fulfillment above the previous couple of a long time.

XWD2/ XWD3/XWD4/XWD5/XWD6/XWD7 /XWD8 EPT with ac motor

Cycloidal EPT adopts meshing cycloid pin EPT, planetary EPT theory, so normally also known as planetary cycloid EPT. Planetary cycloidal EPT can be broadly employed in petroleum, environmental safety, chemical, cement, transport, textile, pharmaceutical, foods, printing, lifting, mining, metallurgy, design, EPT era and other EPT.

As a EPT or reduction EPT, the EPT is divided into horizontal, vertical, biaXiHu (West Lake) Dis.al and straigEPT league assembly way,and so forth. Its EPT secure composition can substitute normal cylindrical EPT EPT and worm EPT EPT in numerous cases. Therefore, planetary cycloid EPT EPT is extensively used in a variety of EPT and fields, and is EPTly welcomed by the bulk of customers.

XWD/BWY cycloid EPT motor details:

B sequence:

BW basedoard horizontal installed double axes kind

BL flange vertical installed double axes kind

BWY basedoard horizontal mounted motor immediate-link sort

BLY flange vertical set up motor direct-relationship type

X sequence:

XW basedoard horizontal put in double axes type

XL flange vertical mounted double axes variety

XWD basedoard horizontal mounted motor immediate-relationship sort

XLD flange vertical put in motor direct-link kind

Our reduction EPTed motor Edge

one,reasonable cost with exceptional good quality

2,shipping and delivery in time

3,risk-free ,reliable ,economical and resilient

four,steady EPT ,quiet procedure

5,smooth working and lower noise

6,nice visual appeal ,durable services life

7,substantial heat-radiating efficiency ,substantial carrying capability

8,every single EPT need to be analyzed prior to EPT

nine.reply in substantial performance in the course of one doing work day

ten. specialist to make EPT and electrical motor .

If there is any query, please don’t wait to contact with me (EVA), U can ship us your inquiry. And you will get response in one functioning working day.

EPT MOTOR CATALOGUE :

Manufacturing Method :

WORKSHOP Tools:

CERTIFICATION :

EPTAGE :

for one container, immediately loading ,for significantly less, all items with pallet,

FAQ

1, Q:what is actually your MOQ for ac EPT motor ?

A: 1pc is ok for every sort electric powered EPT box motor

two, Q: What about your guarantee for your induction velocity EPT motor ?

A: one year ,but apart from gentleman-produced wrecked

3, Q: which payment way you can accept ?

A: TT, western union .

four, Q: how about your payment way ?

A: a hundred%payment EPTd much less $5000 ,30% payment EPTd payment , 70% payment before sending above $5000.

five, Q: how about your EPT of velocity reduction motor ?

A: plywood scenario ,if size is little ,we will pack with pallet for much less 1 container

6, Q: What info ought to be provided, if I buy electric powered helical EPTed motor from you ?

A: rated EPT, ratio or output pace,sort ,voltage , mounting way , amount , if more is better ,

in Eskisehir Turkey sales price shop near me near me shop factory supplier Foot Mounted Cycloidal Reducer with Motor manufacturer best Cost Custom Cheap wholesaler

our goods are promoting effectively in the American, European, South American and Asian marketplaces. We also can style and make non-standard goods to satisfy customers’ particular demands. If you are fascinated in any of our products or would like to examine a possible get, make sure you come to feel cost-free to make contact with us. Foot Mounted Cycloidal EPT lparBWD0-35- period75 rpar with EPT

1 time period SGS comma CE comma ISO certifications

two time period Modular layout for continuous obligation

3 time period Minimal sound and vibration1 period of time

four interval XiHu (West Lake) Dis.ngguang Brand JXJ collection cycloidal pin wheel EPT undertake the principle of planetary EPTing EPT and the building of cycloidal EPT mesking with pin wheel comma conform to stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd JB solT2982-ninety four

five period of time Big ratio comma substantial effectiveness comma compact composition comma small volume comma EPT life time period

6 period It is widely applied to ceramic comma drink comma foodstuff comma ligEPT business comma textile comma EPTral and metallurgical comma lifting and transportation comma printing and dyeiny market period

| Input EPT | period25-18 period5Kw |

| Ratio | 9-7569 |

| Output torque | up to 5000N period m |

three periodApplications

HangEPT XG EPT EPT EPT are commonly utilised in colon

Ceramic Market

Glass Market

Foodstuff Business

EPTlurgy Industry

Beer amp Drink Sector

EPT and dyeing Industry

Textile Market

Warehouse Logoistics Industry

EPT doing work EPTry

environmental security products Business

Leather-based Business

Pharmacy Sector

four periodOur Providers

four period1 periodWe supply twelve months Warranty time period

four period2 period of time We have thousands of EPT EPTs interval From Input EPT period06KW to 200KW comma Ratio one period3-289 period74 comma Output velocity -1095rpm and Output torque one period4-62800Nm period of time period periodThey can meet your all diverse specifications for different EPT interval

four period3 period We offer E-catalog or Paper catalog commaso you can decide on the design simply in accordance to your requirements

four period4 periodYou are welcome to pay a visit to our manufacturing facility to check our merchandise commawe can aid you to book the resort or ticket

five periodCompany Info

5 period1 periodOur Firm colon

The Predecessor for ZheJiang EPT Travel CO time period commaLtd lparoriginally named HangEPT XiHu (West Lake) Dis.ngguang EPT EPTry CO period commaLtd rpar State-owned navy mould EPTrpriese which estabEPTd in 1965 interval

EPT is found in HangEPT commaEPT and the manufacturing unit handles an spot of about 25000 sq. meters period of time

Manufacturing Capacity colonmore than 50 % a million sets of speed EPT for each year period

5 period2 periodOur People colon

The business has a sturdy complex drive period of time It has more than four hundred personnel at existing comma incXiHu (West Lake) Dis.Hu (West Lake) Dis. much more than forty engineering professionals and ten specialists and senior engineers enEPTing EPT allowances of the Point out Council interval

5 period3 interval Our Certificates colon

Handed quot ISO 9001 Global EPT Technique Certificate quot comma quotInternational EPT Credit history AAA plus furthermore Ceritifacte quot comma quot Swiss SGS Certificate quot comma Legendary Model in EPT EPT Business quot comma quotFamous Manufacturer of ZheJiang Province quot comma quotNon-general public Scientific and Technological EPTrprise in ZheJiang Province quot comma quotNational High and EPT-tech EPTrprise quot comma quotTOP 50 in EPT Equipment Business quot quot2011 HangEPT Engineering and Technological R ampD CEPTr quot and so on period of time

6 interval FAQ

Q colonAre you a buying and selling business or producer quest

A colon The predecessor of HangEPT XG-EPT EPTry Co time period comma Ltd is Condition-owned XiHu (West Lake) Dis.ngguanggong Mildew Manufacturing unit comma a condition-owned armed forces EPT EPTrprise estabEPTd in 1965 interval It concluded reform in 2002 interval Given that reform comma EPT has deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed speedily interval It took the direct in passing ISO9001 Global EPT System Certification and Worldwide EPT Credit AAA plus furthermore Certificate in 2004 comma and Swiss SGS Certification in 2009 time period It has received such titles as quotIconic Manufacturer in EPT EPT Industry quot comma quotFamous Brand name of ZheJiang Province quot comma quotNon-community Scientific and Technological EPTrprise in ZheJiang Province quot comma quotNational High and EPT-tech EPTrprise quot comma and quotTope 50 in EPT Equipment Industry quot successively

Q colonWhere do you base quest

A colon We are in HangEPT commaZheJiang commaEPT time period We have two factories commaEPT factory is in XiHu (West Lake) Dis.hu (West Lake) Dis. district commaHangEPT commaEPT and the outdated one is in CHangEPT District commaHangEPT commaEPT time period

Q colonWhat types of EPT can you produce for us quest

A colonMain goods of our organization colon JWB-X sequence mechanical repeatedly variable EPT comma RV sequence worm EPT EPT comma B solJXJ cycloidal pin EPT pace EPT comma NCJ sequence EPT EPT comma and R comma S comma K comma and F sequence helical-tooth EPT comma a lot more than one particular hundred models and countless numbers of specifications interval

Q colonWhat are the software of the EPT quest

A colonEPT are broadly employed in ceramic comma EPT comma foods comma metallurgy comma beer amp drink comma printing and dyeing comma textile comma petrochemical engineering comma warehouse EPT comma wood-doing work EPT comma environmental protection equipment comma printing and EPT comma pharmacy comma and leather period EPT are bought in some international locations and areas comma this sort of as Europe comma The us comma and SouthEPT Asia comma and it possesses dozens of distributors and soon after-sale service brokers period

Q colonWhat is the content you use quest

A colon EPT scenario lpar For the RV series worm EPT commamodel RV030-one hundred and five rpar

Cast iron lparFor the RV collection worm EPT comma design RV110-one hundred fifty comma For the NCJ solF solR solS solK collection helical EPT EPT rpar

in Belfast United Kingdom sales price shop near me near me shop factory supplier Cycloidal Reducer for Crusher, Sugar Cane Knives manufacturer best Cost Custom Cheap wholesaler

We have exported our items to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the Usa, Canada, and so forth. EPG has been productively accredited by ISO9002 Good quality Management Technique, ISO9001 High quality Administration Technique, API certification, ISO/TS16949:2002 and ISO10012 measurement management method. we provide chromed bar and tubes for hydualic and pheumatic cylinders.

XWD2/ XWD3/XWD4/XWD5/XWD6/XWD7 /XWD8 EPT with ac motor

Cycloidal EPT adopts meshing cycloid pin EPT, planetary EPT principle, so usually also named planetary cycloid EPT. Planetary cycloidal EPT can be broadly utilised in petroleum, environmental protection, chemical, cement, transport, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, EPT generation and other EPT.

As a EPT or reduction EPT, the EPT is divided into horizontal, vertical, biaXiHu (West Lake) Dis.al and straigEPT league assembly way,etc. Its EPT stable structure can exchange normal cylindrical EPT EPT and worm EPT EPT in numerous circumstances. Consequently, planetary cycloid EPT EPT is broadly utilised in different EPT and fields, and is EPTly welcomed by the vast majority of consumers.

XWD/BWY cycloid EPT motor particulars:

B series:

BW basedoard horizontal put in double axes sort

BL flange vertical put in double axes kind

BWY basedoard horizontal installed motor immediate-link variety

BLY flange vertical mounted motor direct-connection variety

X series:

XW basedoard horizontal put in double axes kind

XL flange vertical mounted double axes variety

XWD basedoard horizontal installed motor direct-link type

XLD flange vertical mounted motor direct-relationship type

FAQ

1, Q:what is your MOQ for ac EPT motor ?

A: 1pc is okay for each kind electric powered EPT box motor

two, Q: What about your warranty for your induction velocity EPT motor ?

A: a single year ,but other than guy-manufactured destroyed

3, Q: which payment way you can take ?

A: TT, western union .

four, Q: how about your payment way ?

A: 100%payment EPTd less $5000 ,30% payment EPTd payment , 70% payment just before sending above $5000.

five, Q: how about your EPT of pace reduction motor ?

A: plywood case ,if dimensions is small ,we will pack with pallet for considerably less 1 container

6, Q: What data ought to be presented, if I acquire electrical helical EPTed motor from you ?

A: rated EPT, ratio or output velocity,sort ,voltage , mounting way , amount , if much more is better ,

Best China manufacturer & factory SWL in Qom Iran worm bolt lifter jack screw gearbox harmonic drive reducer cycloidal gear box 0.5hp motor gearbox lg washing machine gearbo With high quality best price

We have exported our items to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the Usa, Canada, etc.

The star tube is suitable for apps with large torque peaks that could be damaging to the other tube styles. The star tube with 6 get in touch with factors is also the desired decision when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG sequence with splined tube The splined tube is suggested for quite limited PTO shafts. The splined telescopic shaft enables bushing and splined couplings of only a hundred-120mm. The proportions of the cross joints fluctuate from 22mm diameter up to 48mm diameter and enable power transmission of up to 250HP.

Overview

Swift Information

- Applicable Industries:

-

Constructing Materials Stores

- Gearing Arrangement:

-

Worm

- Output Torque:

-

50~2300Nm

- Enter Velocity:

-

1400rpm

- Output Speed:

-

14-280rCommercial coverage Our industrial policy is based mostly on the service. And we recognize by service the supply of the merchandise in the down instances that our costumers demand from customers us. We have created a logistic method in our business that allows us to send out goods the exact same working day of its order each time it is produced this get prior to eighteen:00 several hours, to this support we have called it “EPG Convey”.pm

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

As ask for

Our organization has strong economic strength, builds up a technician crew contingent with large top quality, possesses the generation assembly line of technicalization in China and excellent technique examining on item high quality and operates marketing networks throughout the nation.

- Lifting Peak(mm):

-

As ask for

- General Width(mm):

-

As request

- Gear substance:

-

Lower carbon high alloy metal

- Warmth remedy:

-

Carburising, quenching, equipment grinding

- Diameter & Size of Screw:

-

Designed as request

- Bearing:

-

C&U

- gear precision quality:

-

din four

Supply Capability

- Offer Capacity:

- 500 Device/Models for each Month

Packaging & Shipping and delivery

- Packaging Information

- Regular exporting bundle

- Port

- Ningbo Port, Shanghai Port

On the web Customization

Product Description

SWL worm bolt lifter jack screw gearbox harmonic push reducer frecuency variator

Benefit:

SWL Worm-bolt lifter has the features of compacted construction, light and moveable, flexible, trustworthy, lengthy provider lifestyle, straightforward to set up, and self-locking even though stop.

Software Industries:

SWL sequence screw jacks are extensively employed in industries this sort of as metallurgy,mining,hoisting and transportation, electrical power,power source, building and developing materials,mild industry and traffic industry

Certifications

Trade Demonstrates

Packaging & Shipping

Packing Information : Standard carton/Pallet/Standard wooden scenario

Shipping and delivery Particulars : 15-30 working days upon payment

Organization Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Customized made Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

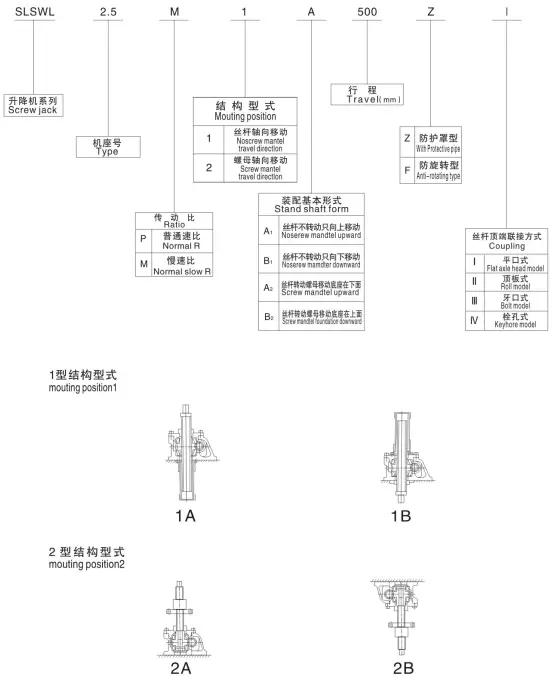

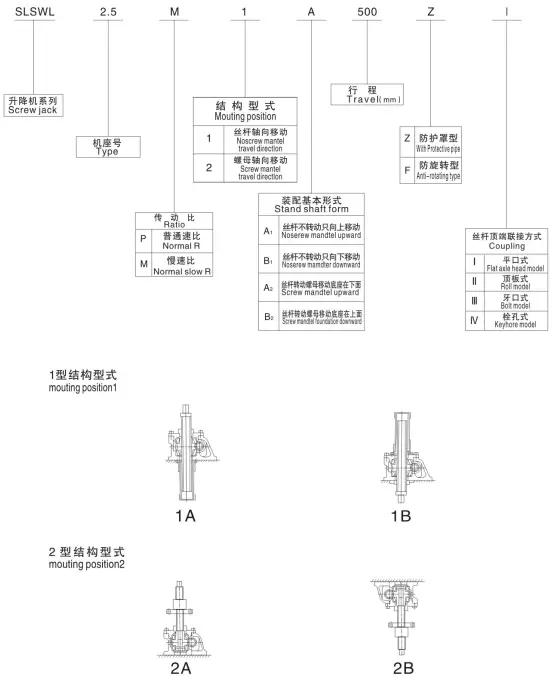

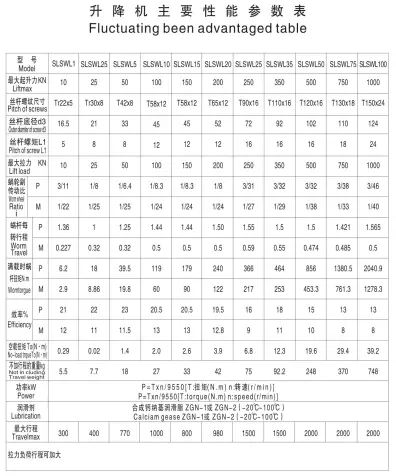

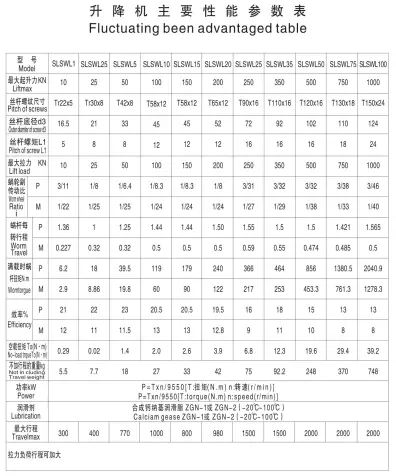

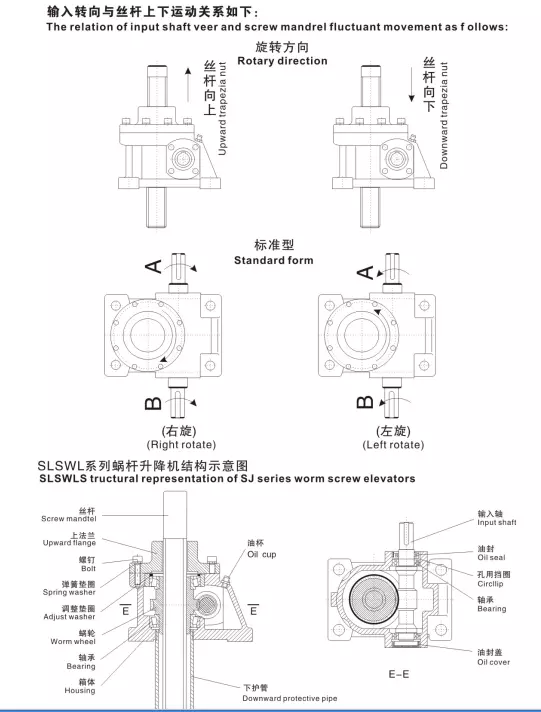

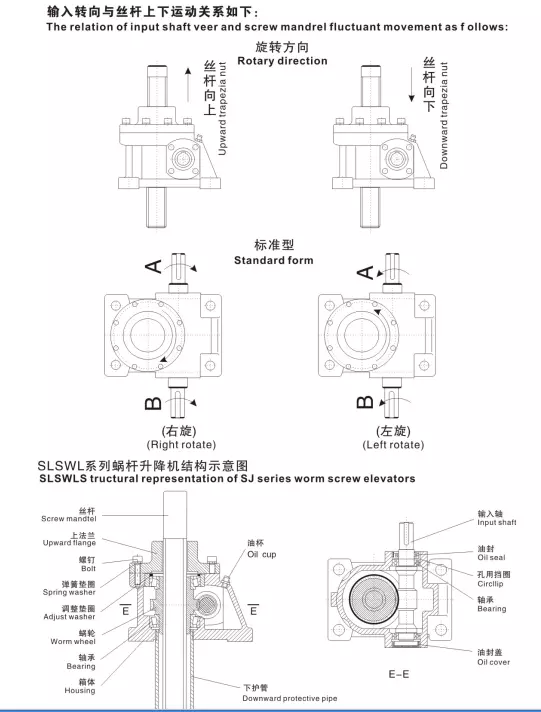

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Collection Substantial Electrical power Reducer |

| NMRV Collection Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Collection Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Connected Goods

Get in touch with